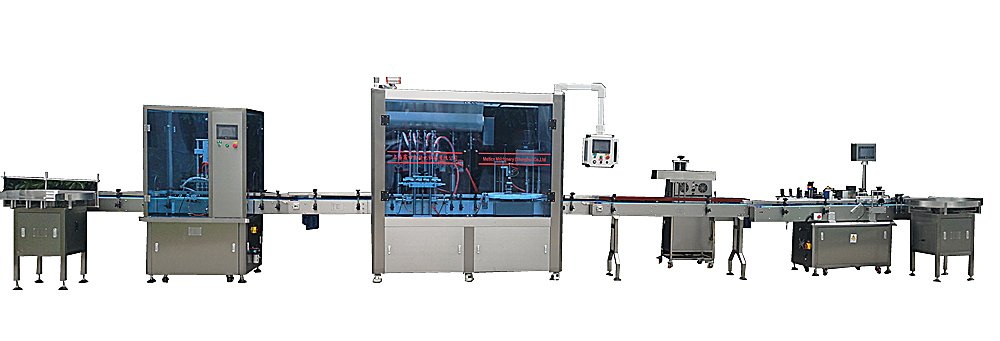

Application:

- This line is widely used in food, beverage, pharmaceutical, health care industries 100-1000 ml

plastic (glass) bottle filling capping, such as oral liquid, topical agent, syrup, vaccine, nails water etc.

Spec and Feature

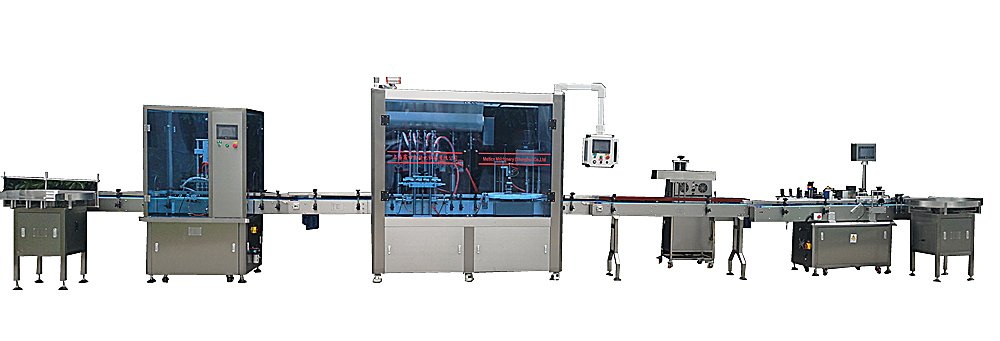

- The line includes: Turn Table, Filler, Caps Feeding, Screw Capper, Labeler

- Automatic run, PLC control, Operate on Touch Screen,

- Suitable for the volume 10-500 ml liquid or low viscosity products

- Applicable for many types of caps: screw caps, Anti-Theft ring screw caps, Spiral Caps, Aluminium Caps and etc

- It adopts 4 nozzles piston type filling, rotating plate positioning capping method. No bubble, no spill.

- Filling accurate, good performance, easy to maintain and operate

Work process:

- 1) Put bottles on turn table feeding bottles to filling machine automatically

- 2) Bottles conveyed to filling machine to fill automatically

- 3) Bottle conveyed to capping machine cap automatically after filling

- 4) Bottle conveyed to labeling machine label automatically

- 5) Collect bottles with a turn table(optional)

Parameter:

| Speed |

2000-3000bph (customizable) |

| Filling accuracy |

more than 99% |

| Filling volume |

100-1000ml, 200-2000ml, … 500-5000ml(customizable) |

| Filling method |

piston + servo motor driven, diving nozzles |

| Power supply |

220V 50hz 5kw |

| Bottles applicable |

a wide shape range |

|

Application

|

Liquid or viscosity products |

| Total length |

8merers |

| Feature |

PLC, touch screen, tank, level meter |

Turn table and bottle washing machine:

Filling capping machine in one:

Labeling machine:

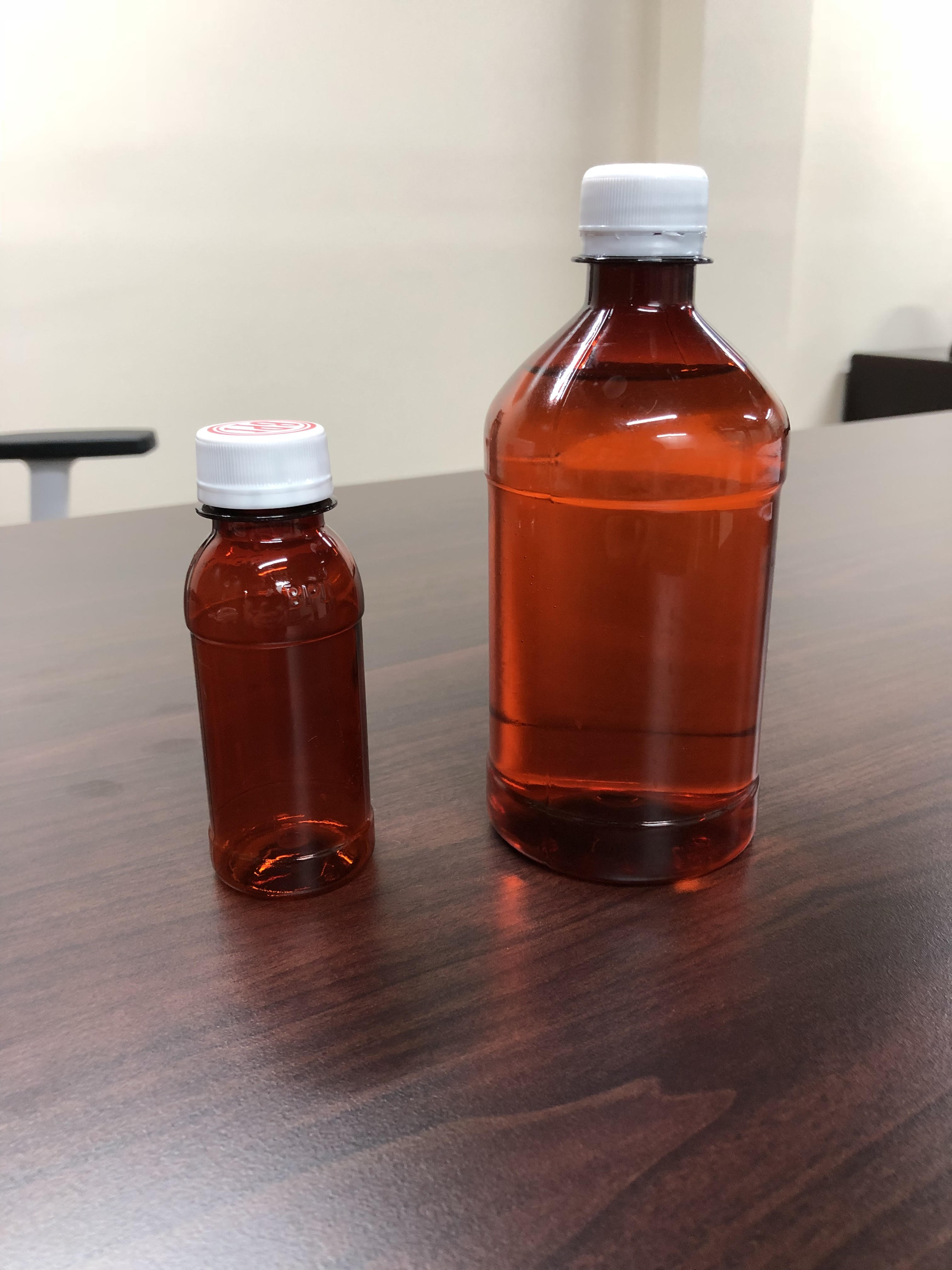

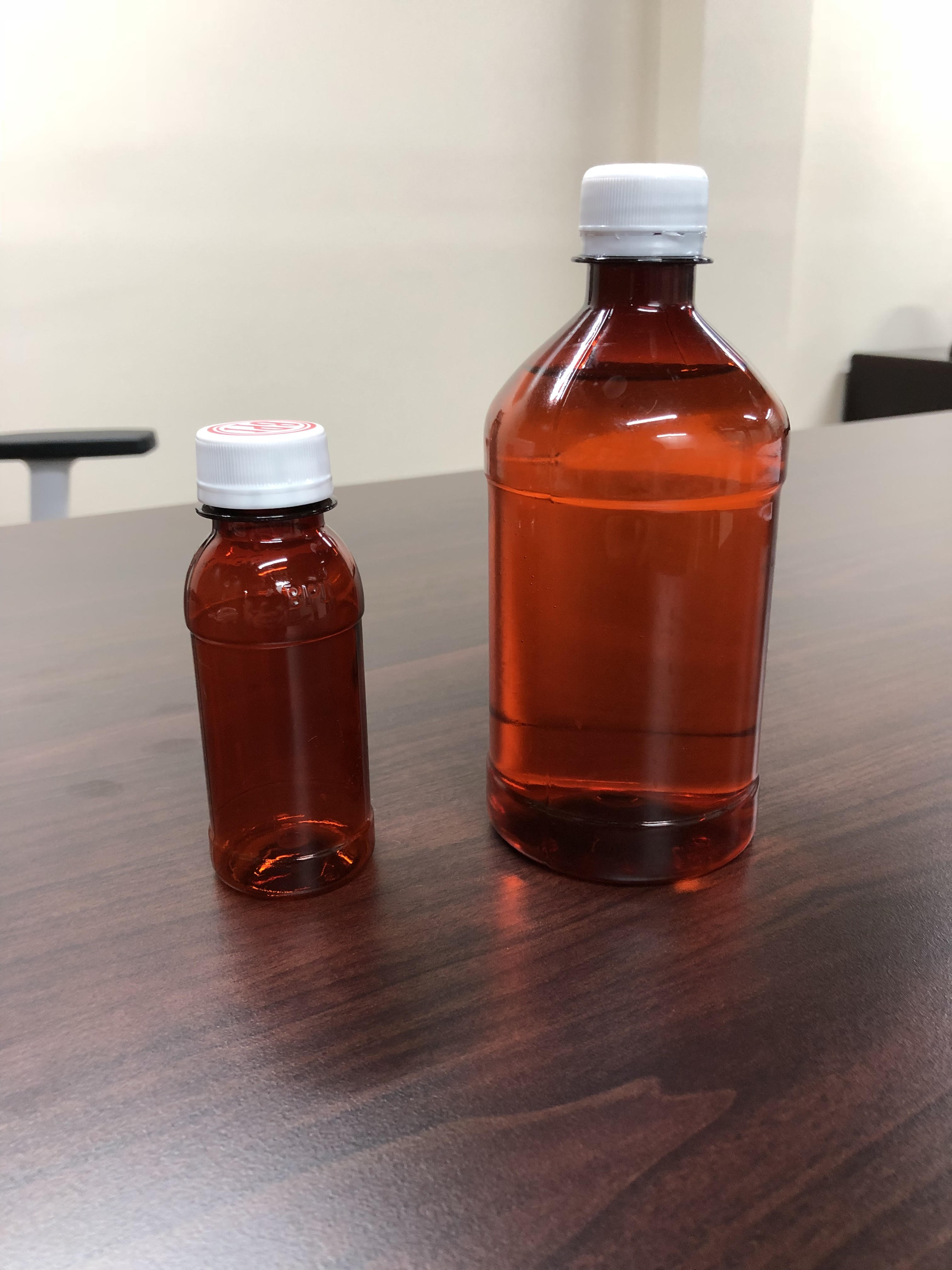

Samples display: